Service organisation consisting of specially trained technicians in every area of expertise, in more than 21 locations in the Nordic region

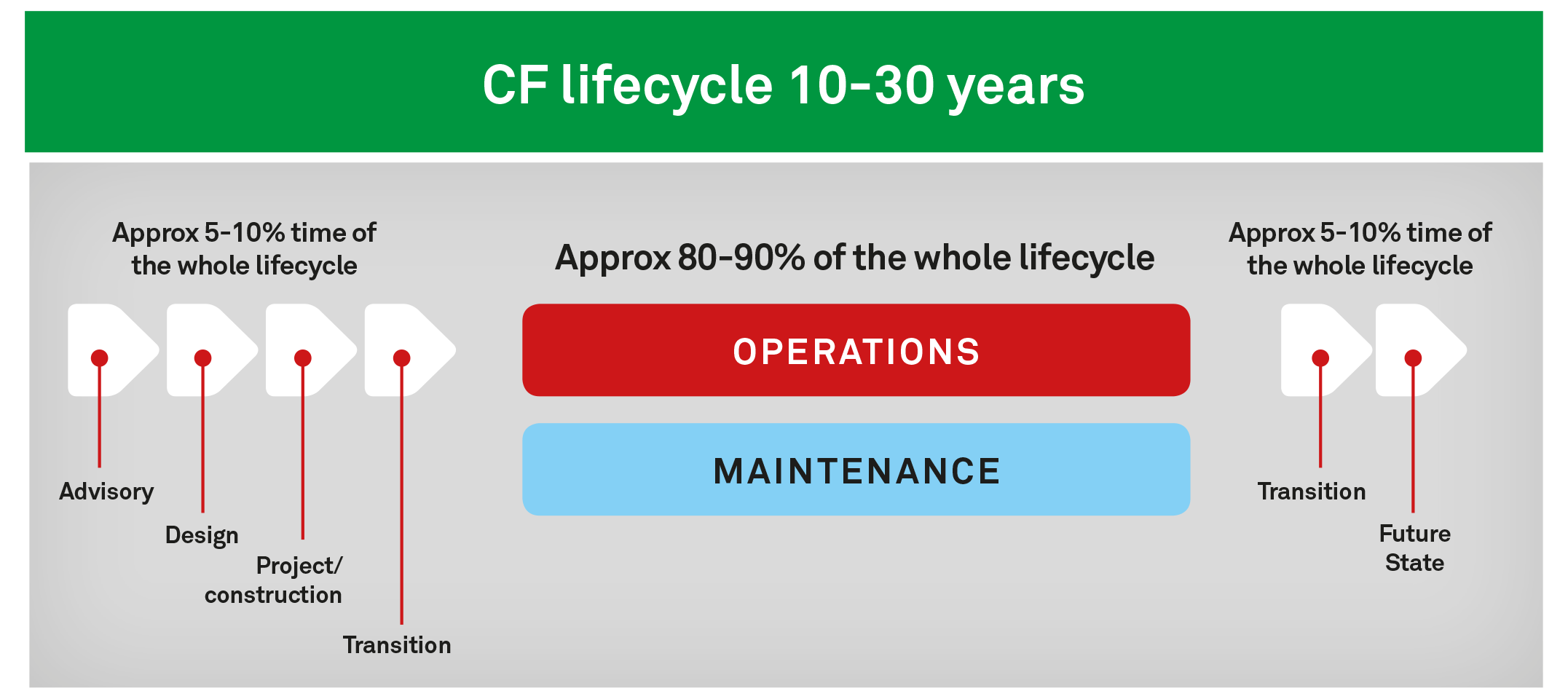

As the leading supplier of solutions for critical infrastructure in the Nordic region, and with over 30 years of industry experience, Coromatic have delivered many different projects in the Nordic region. Demand for qualified skills in service and maintenance, and for ensuring uninterruptible operation 24/7/365, grows every year.

Coromatic have a service organisation consisting of specially trained technicians in every area of expertise. All technicians are certified in our various suppliers’ products and trained to handle facilities in critical environments.

In addition, we have a network of partners who provide various services and specialisations so that we can offer to take overall responsibility for our customers. We have more than 220 specialised service technicians across more than 21 locations around the Nordic region.

Order – simple and clear – the way service should be

All communication and feedback takes place via our service co-ordinators, who handle all issues and service activities. All activities and issues are entered into our service system and stored over time. This way our customers can easily access performed and planned activities, as well as all documentation of the facility.

020–45 05 05 – a single service number – many contacts – Via our single point of contact (SPOC) you can quickly and easily get in touch with our service organisation, no matter the time of day you need help. A single call solves your problems and handles all the included products and functions in your facility.

Service activities in accordance with our environmental policy and our environmental goals

In all our service activities, we work in accordance with our environmental policy and goals to effectively minimise the environmental impact. This means that we use environmentally friendly products, work to ensure that all transport takes place in a way that is beneficial to the environment, recycle all material in an environmentally efficient way, and that we follow environmental developments in order to increase our know-how and get even better. We also inform and train our technicians in environmental issues.

The whole is important

Coromatic’s strength is our knowledge of the whole. No facility is stronger than its weakest link. Our experience, from how to design and build facilities to how these should be serviced and maintained over time, is our strength, and benefits our customers.

Preventive service to avoid malfunctions

Coromatic work to ensure that the customer’s operating environment is maintained and serviced through regular and scheduled activities to prevent any operational disruptions. Preventive servicing of the facility’s functions is performed regularly by our technicians in each functional area. Service visits have varying scopes, depending on function, facility structure and applicable laws and regulations. A servicing schedule indicates when you can expect your visit from our technicians and, after the service has been performed, you will be informed of a service report being available in our service system.

Service agreement – a guarantee of high availability

Through a service agreement with Coromatic, you get an assurance of continuous maintenance of your operating environment and a guaranteed response time for when a technician must be on site. When we draw up an agreement, we take your specific needs into account. Your requirements for availability, finances and type of facility are decisive factors in terms of the service level to be applied.

Adjustment work

At each service, changed conditions in the system are checked and necessary adjustments are made. Our service technicians carry out certain adjustment work in connection with servicing, and they report and advise on whether major changes are necessary.

Technicians are always on site according to the agreed service level

In the event of any faults or malfunctions, service technicians can be called on site. This can be done automatically, via alarms from the alarm system, or by your operating personnel. Around the clock – all year round – there will be a service technician on site to take action according to the agreed service level.